System Signal Integrity

×

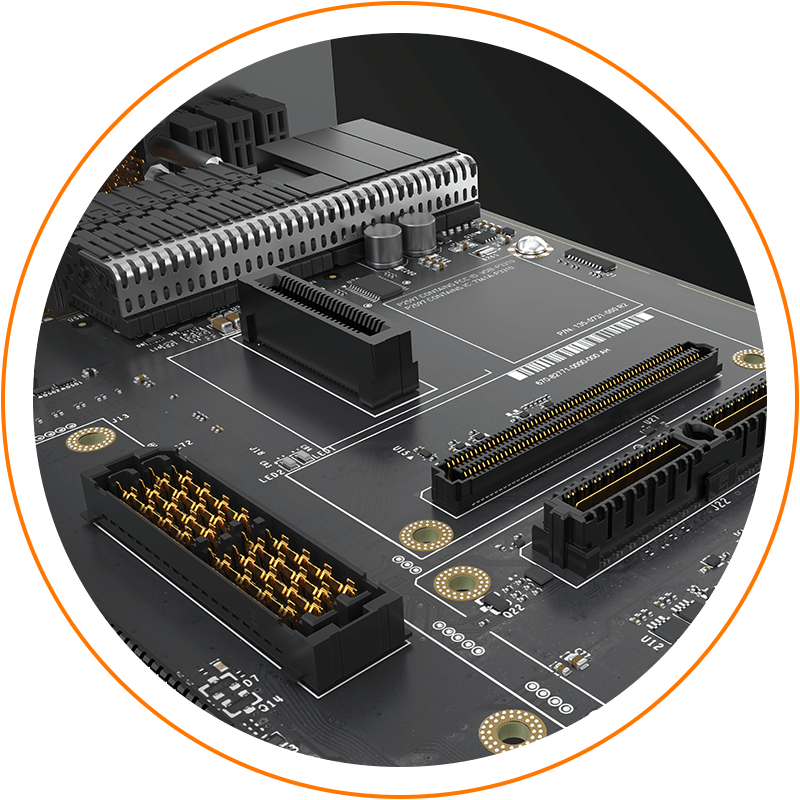

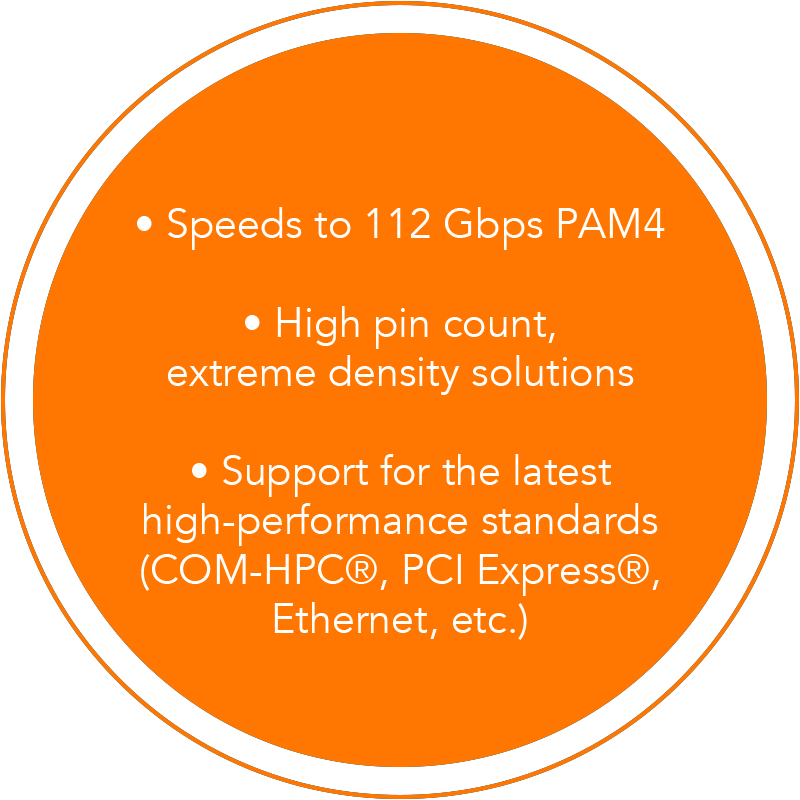

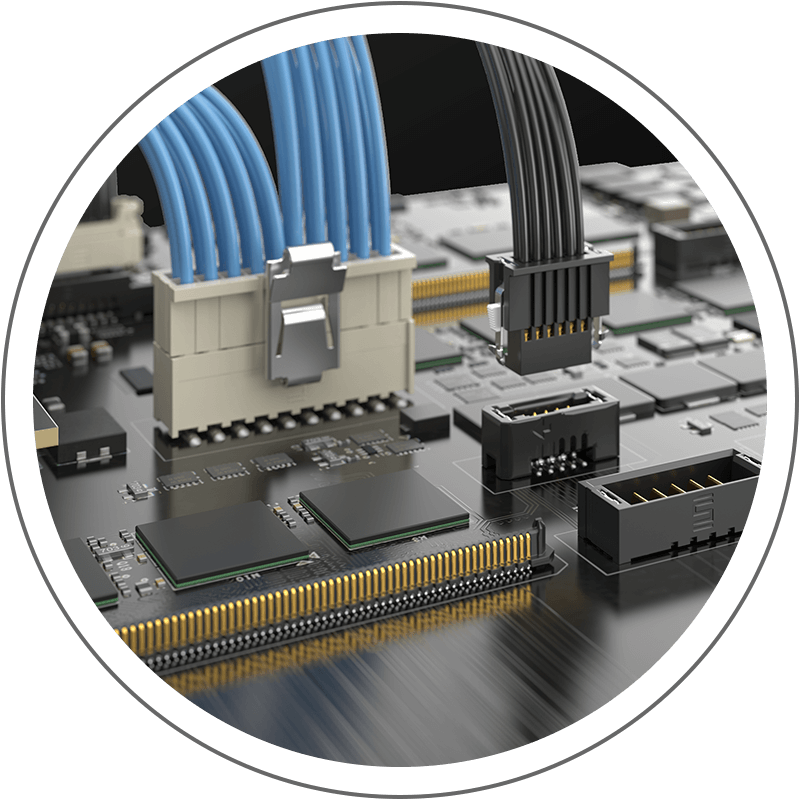

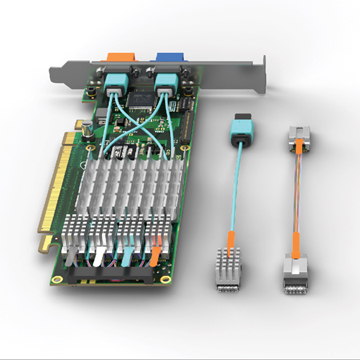

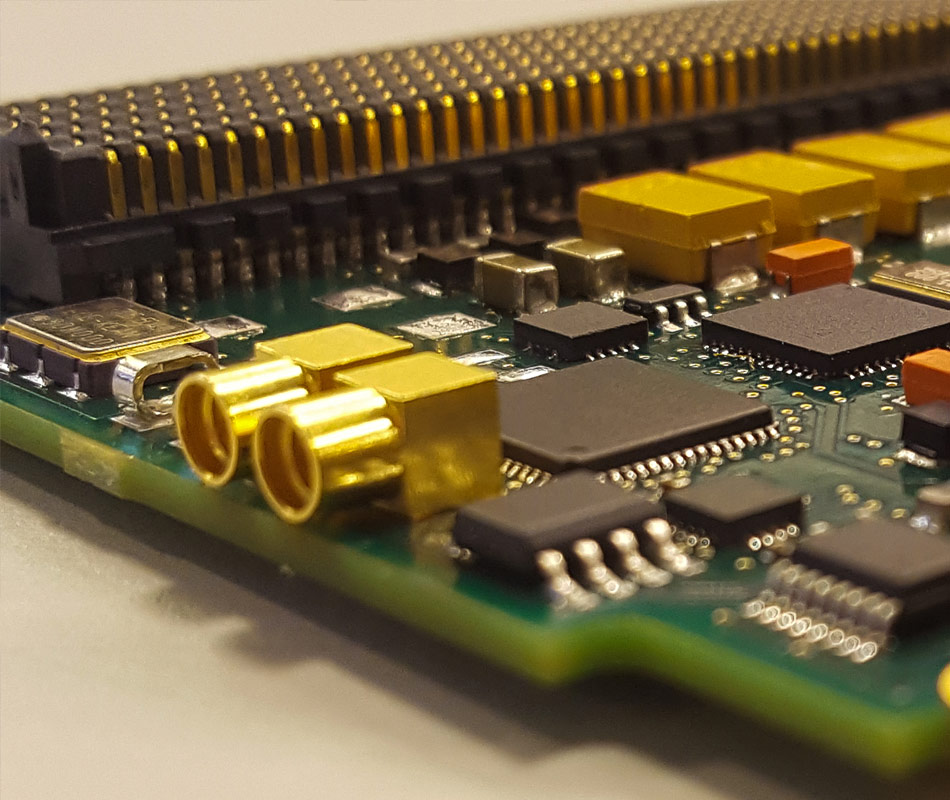

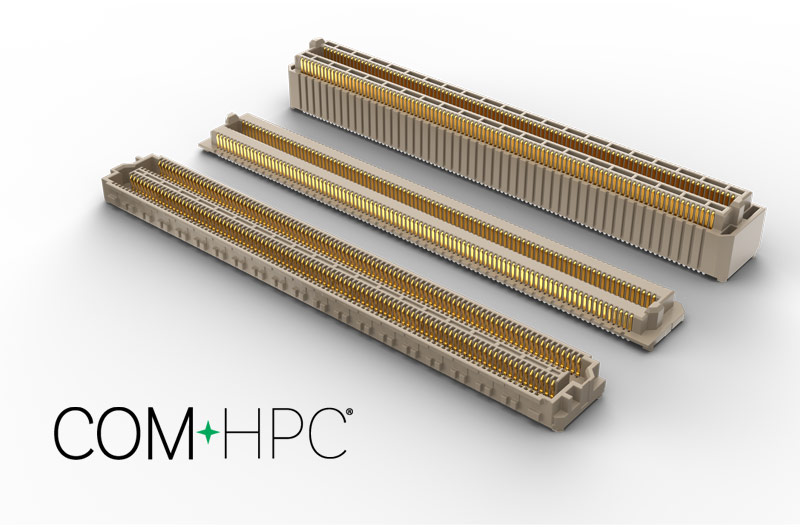

Samtec offers industry-leading signal integrity expertise to help optimize the entire high-performance system.

Samtec products are tested to or beyond industry standards to ensure quality and performance in a variety of applications.

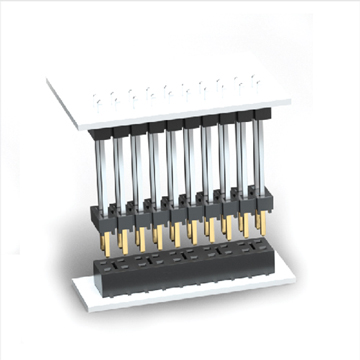

SEVERE ENVIRONMENT TESTING

Severe Environment Testing is a Samtec initiative to test our products beyond typical industry standards and specifications, many set forth by common requirements for rugged industries. Several of our products undergo additional testing to ensure they are more than suitable for industrial, military, automotive, space, and other extreme applications.

TESTING INCLUDES:

- VITA™ 47.1 Module Insertions

- VITA™ 47.3 Humidity

- VITA™ 47.1 Operating Shock Class OS2

- VITA™ 47.1 Vibration Class VS3

- Exceeds VITA™ 47.1 Temperature Cycling Class C4

- Exceeds VITA™ 47.1 Non-Operating Temperature Class C4

- VITA™ 47.1 Electrostatic Discharge Resistance

- Exceeds VITA™ 47.1 Altitude for DWV

Samtec's SET products are approved for NASA Class D missions that require high-reliability, quick-turn and cost-effective solutions for LEO satellites, SmallSats, CubeSats and other space exploration applications.

Samtec also utilizes NASA outgassing data to determine if certain products meet NASA's ASTM E595-77/84/90 test requirements. Visit outgassing.nasa.gov for data.

Please visit the Severe Environment Testing page or contact set@samtec.com for more information.

| TEST |

SET |

E.L.P.™ |

DQT |

| Gas Tight |

X* |

X* |

X |

| Normal Force |

X* |

X* |

X |

| Thermal Aging |

X* |

X* |

X |

| Mating / Unmating / Durability (240 Hrs) |

X (100% RH, 250 Cycles) |

X* (90-98% RH, 100 Cycles) |

X (90-98% RH, 100 Cycles) |

| IR / DWV |

X (At Altitude of 70,000 Feet) |

X* |

X |

| CCC |

X* |

X* |

X |

| Mechanical Shock / Random Vibration / LLCR & Nanosecond Event Detection |

X (40 G Peak, 11 ms, Half Sine & 12gRMS, 5 - 2,000 Hz, 1 Hr / Axis) |

X* (100 G Peak, 6 ms, Half Sine & 7.56gRMS Avg, 2 Hr / Axis) |

X (100 G Peak, 6 ms, Half Sine & 7.56gRMS Avg, 2 Hr / Axis) |

| Temperature Cycling (500 Cycles) |

X |

N/A |

N/A |

| Non-Operating Class Temperature |

X |

N/A |

N/A |

| Electrostatic Discharge (ESD) |

X |

N/A |

N/A |

| 10 Year MFG (Mixed Flowing Gas) |

N/A |

X |

N/A |

| Mating Cycles (250 to 2,500) |

N/A |

X |

N/A |

| *Completed as part of initial Design Qualification Testing (DQT). E.L.P.™ and SET testing are performed in addition to DQT. |

×

EXTENDED LIFE PRODUCT™

E.L.P.™ products are tested to rigorous standards, which evaluate contact resistance in simulated storage and field conditions.

- 10 year Mixed Flowing Gas (MFG)

- High Mating Cycles (250 to 2,500)

- Certain plating and/or contact options will apply

For complete details on Samtec's E.L.P.™ program, a list of qualifying products and test results, visit samtec.com/ELP or email the Customer Engineering Support Group at ASG@samtec.com

| TEST |

SET |

E.L.P.™ |

DQT |

| Gas Tight |

X* |

X* |

X |

| Normal Force |

X* |

X* |

X |

| Thermal Aging |

X* |

X* |

X |

| Mating / Unmating / Durability (240 Hrs) |

X (100% RH, 250 Cycles) |

X* (90-98% RH, 100 Cycles) |

X (90-98% RH, 100 Cycles) |

| IR / DWV |

X (At Altitude of 70,000 Feet) |

X* |

X |

| CCC |

X* |

X* |

X |

| Mechanical Shock / Random Vibration / LLCR & Nanosecond Event Detection |

X (40 G Peak, 11 ms, Half Sine & 12gRMS, 5 - 2,000 Hz, 1 Hr / Axis) |

X* (100 G Peak, 6 ms, Half Sine & 7.56gRMS Avg, 2 Hr / Axis) |

X (100 G Peak, 6 ms, Half Sine & 7.56gRMS Avg, 2 Hr / Axis) |

| Temperature Cycling (500 Cycles) |

X |

N/A |

N/A |

| Non-Operating Class Temperature |

X |

N/A |

N/A |

| Electrostatic Discharge (ESD) |

X |

N/A |

N/A |

| 10 Year MFG (Mixed Flowing Gas) |

N/A |

X |

N/A |

| Mating Cycles (250 to 2,500) |

N/A |

X |

N/A |

| *Completed as part of initial Design Qualification Testing (DQT). E.L.P.™ and SET testing are performed in addition to DQT. |

×

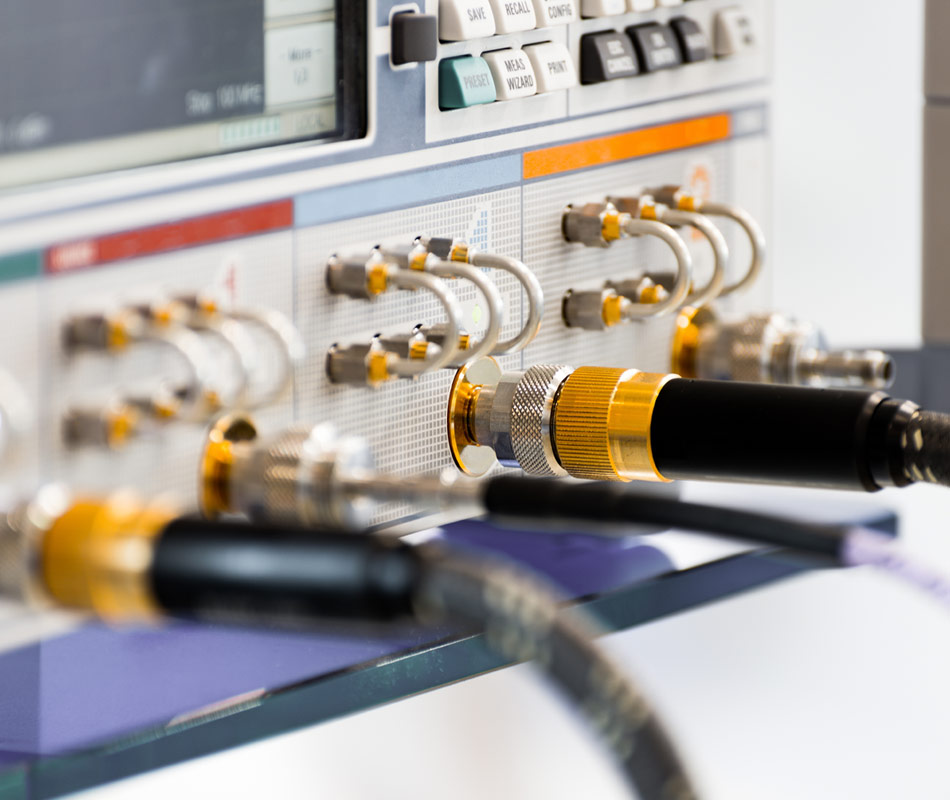

DESIGN QUALIFICATION TESTING

All Samtec series undergo Design Qualification Testing (DQT), which includes:

- Gas Tight

- Normal Force

- Thermal Aging

- Mating/Unmating/Durability

- IR/DWV

- Current Carrying Capacity (CCC)

- Mechanical Shock/Random Vibration/LLCR

- Mechanical Shock/Random Vibration/Event Detection

| TEST |

SET |

E.L.P.™ |

DQT |

| Gas Tight |

X* |

X* |

X |

| Normal Force |

X* |

X* |

X |

| Thermal Aging |

X* |

X* |

X |

| Mating / Unmating / Durability (240 Hrs) |

X (100% RH, 250 Cycles) |

X* (90-98% RH, 100 Cycles) |

X (90-98% RH, 100 Cycles) |

| IR / DWV |

X (At Altitude of 70,000 Feet) |

X* |

X |

| CCC |

X* |

X* |

X |

| Mechanical Shock / Random Vibration / LLCR & Nanosecond Event Detection |

X (40 G Peak, 11 ms, Half Sine & 12gRMS, 5 - 2,000 Hz, 1 Hr / Axis) |

X* (100 G Peak, 6 ms, Half Sine & 7.56gRMS Avg, 2 Hr / Axis) |

X (100 G Peak, 6 ms, Half Sine & 7.56gRMS Avg, 2 Hr / Axis) |

| Temperature Cycling (500 Cycles) |

X |

N/A |

N/A |

| Non-Operating Class Temperature |

X |

N/A |

N/A |

| Electrostatic Discharge (ESD) |

X |

N/A |

N/A |

| 10 Year MFG (Mixed Flowing Gas) |

N/A |

X |

N/A |

| Mating Cycles (250 to 2,500) |

N/A |

X |

N/A |

| *Completed as part of initial Design Qualification Testing (DQT). E.L.P.™ and SET testing are performed in addition to DQT. |

×

Samtec offers a complete library of online technical resources to help streamline the design and development process.